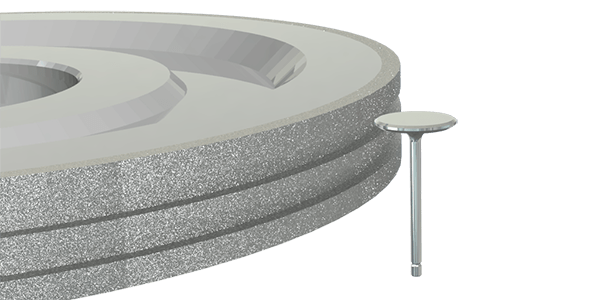

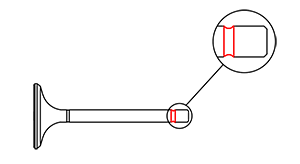

1. Grinding of valve head: (valve material: high nickel material)

| Product name |

Rough grinding head (external circle + cone) 60° grinding wheel |

| Specifications |

510D-30T-203.2H-60° |

| Binding agent |

Electroplated |

| Weight |

20-25Kg |

| Dynamic balance |

≤0.5g |

| Installation requirements |

Radial runout&end runout ≤0.003mm |

| Workpiece |

| Margin |

φ0.5-1mm |

| Material |

Nickel 30(High-nickel) |

| Working accuracy |

Rz≤10μm |

| Other requirement |

No scratches, burns, vibration marks and other defects on the surface |

| Machining effect |

| Processing life |

100-120 thousand Pcs |

| Roughness |

Rz≈5μm |

| Processing time |

10s |

| Stability |

Batch processing size is stable, no need to debug |

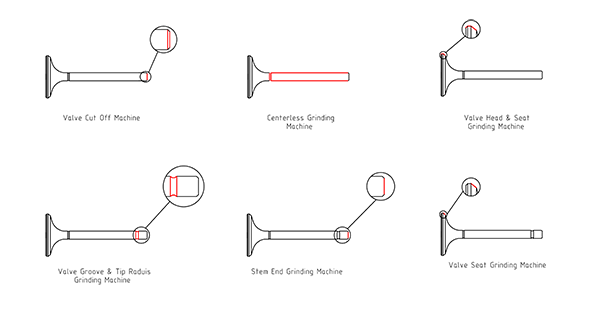

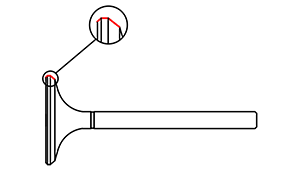

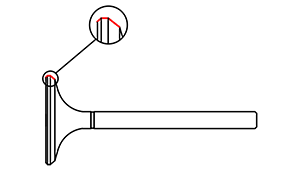

2. Grinding of valve lock groove: (valve material: martensite/austenite)

| Products name |

Locking groove grinding wheel |

| Specifications |

400D*24T*160H |

| Binding agent |

Electroplated |

| Weight |

16-20kg |

| Dynamic balance |

≤0.5g |

| Installation requirements |

Radial runout&end runout ≤0.003mm |

| Workpiece |

| Margin |

φ1.2mm |

| Material |

Martensitic heat resistant steel |

| Working accuracy |

Ra≤0.8μm |

| Other requirement |

The grinding surface has the same texture, no chatter marks, burns, and no burrs. |

| Machining effect |

| Processing life |

120-150 thousand Pcs |

| Roughness |

Ra≤0.8μm |

| Processing time |

7~8s |

| Stability |

Batch processing size is stable, no need to debug |